3M Scotchshield Safety & Security Window Film System S2400

A New Generation of Security Film

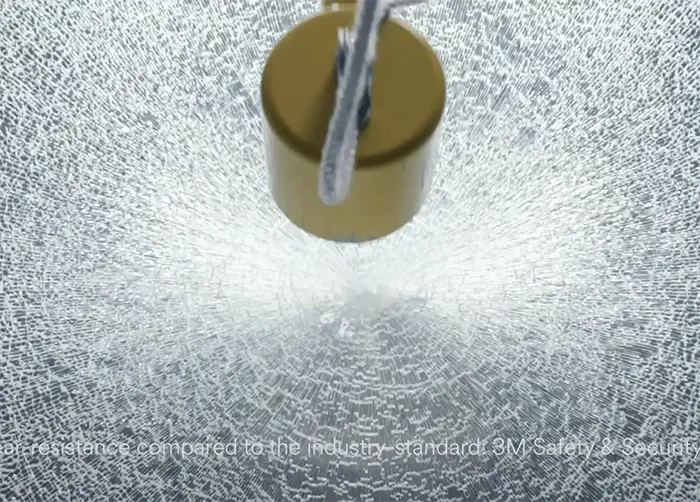

3M S2400 Window Film and Impact Protection Adhesive can help prevent unwanted entry, harden school windows, minimize damage caused by spontaneous glass breakage, and turn standard glass into safety glazing.

S2400 is tested to the following standards:

- ANSI Z97.1

- UL 972

- ASTM F1233

- ASTM E1886 & E1996

3M Safety & Security Window Films, such as S2400, are not tested to ASTM F3561-22. Learn More.

At a Glance

School Safety Hardening

Delayed Entry

Incredible Tear Resistance

Urethane-Based Clear, Invisible Protection

Tested to ASTM F1233

Tested to ASTM E1886 & E1996

Passes UL 972

Warrantied by 3M

Comparing Security Window Films: Urethane vs. PET

The Old Way

S2400 | 22-mil PET | Advantage | |

|---|---|---|---|

0.024" | 0.022" | S2400 | |

560% | 130% | S2400 | |

77 lbs/in | 469 lbs/in | 22-mil PET | |

3,200 psi | 22,000 psi | 22-mil PET |

The New Way

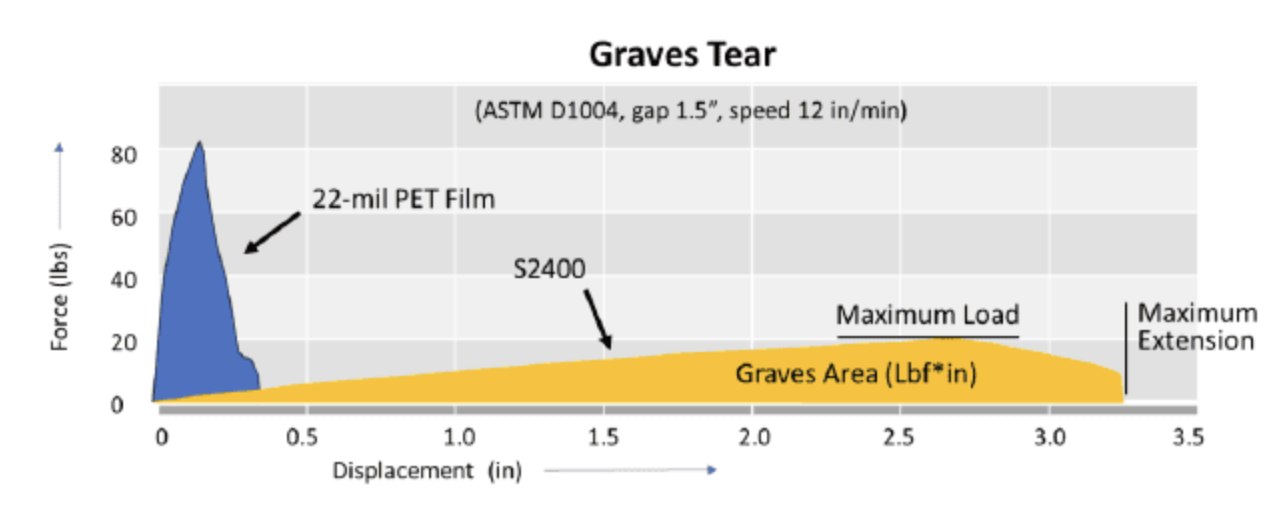

3M testing shows that a film’s Graves Tear measure is a valid indication of the film’s ability to hold broken glass in place when the glass is exposed to some sort of trauma (forced entry, bomb blast, windstorm, etc). What is being measured by Graves Tear is the force necessary to tear a film at a stress concentration point.

The graph below shows what happens when you elongate (stretch) 3M S2400 and a 22-mil PET-based film. As you stretch the films, the resisting force is measured and recorded. More force is required to break the PET-based film but that film breaks much faster than S2400. The area under both curves is then calculated and compared to determine which film has greater Graves Tear. S2400 has 66% more area under its curve than does the 22-mil PET-based film, thereby allowing S2400 to better absorb energy from an impact.

S2400 | 22-mil PET | ||

|---|---|---|---|

Graves Tear | 24.6 lbf*in | 14.8 lbf*in |

Summary: Which Film Offers Better Protection?

Product Information

Film Construction | Urethane (TPU) |

Film Thickness | 24 mils thick (.024”) |

Roll Widths | 60” & 72” |

Adhesive Type | Pressure Sensitive (PSA) |

Warranty | Residential: Limited Lifetime |

Do you need to be a 3M Authorized Window Film Dealer to purchase? | Yes |

Brochure | |

Technical Data Sheet | |

Warranty | |

Family Card |