3M ULTRA S800 Safety & Security Window Films

Protect People & Property

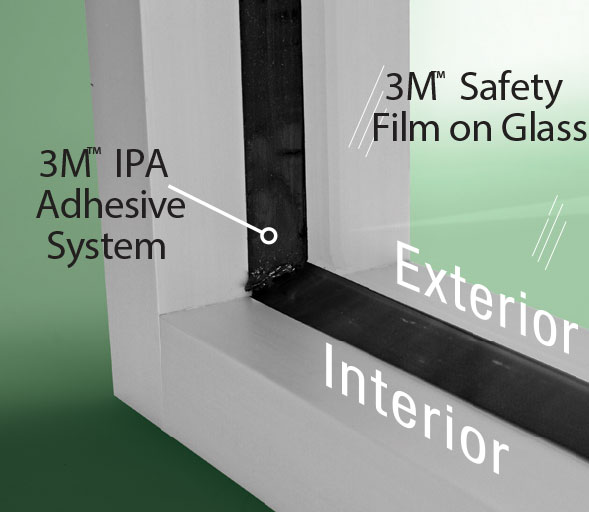

3M ULTRA S800 is an 8-mil thick clear safety and security film that was introduced in 2014. Since then, it has been used throughout the world for those looking to protect people, property, and continuity of operations from the dangers associated with broken glass. Independent testing has shown that when installed in conjunction with 3M’s Impact Protection Adhesive, 3M ULTRA S800 reduces the harms associated with broken glass due to bomb blasts, blunt force traumas, active shooters, seismic events, windstorms, and spontaneous glass breakage.

3M Company holds the original patent to safety and security window films (also known as fragment retention films) dating back to the late 1960s. Originally developed at the request of the UK government in response to IRA terrorist bombings, 3M has innovated the product significantly over the past 50 years.

At a Glance

School Safety / Delayed Entry

Incredible Tear Resistance

PET-Based Clear Invisible Protection

Warrantied by 3M

Is a Thicker Security Film Better?

3M’s Response: A Multi-Layer Technique

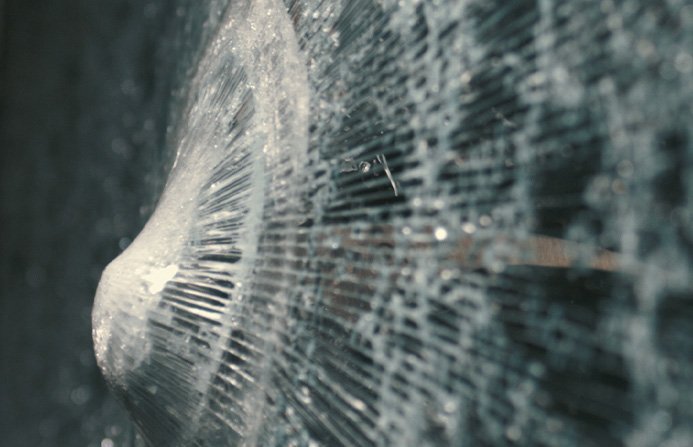

Without sacrificing blast protection (according to third party testing) or building aesthetics, 3M developed a thinner security film consisting of an industry-unique and patented system of interwoven composite polyester layers.

A multi-layered manufacturing technique creates product elasticity to allow the film to “give” with the glass during some sort of trauma (bomb blast, blunt force, windstorm, etc). This “give” provides the glass with a cushion during the related stress and shock.

The main benefit afforded by cross-weaving polyester fibers is that tear resistance is maximized. Regardless of how a window breaks, the applied film will be torn against its grain. Consequently, an 8-mil thick 3M ULTRA film is more difficult to tear than an 8-mil thick standard film. This strong, thin film increases occupant safety without creating the associated optical distortion of thicker films.

Product Information

Film Construction | Polyester (PET) |

Film Thickness | 8 mils thick (.008”) |

Roll Widths | 36”, 60” & 72” |

Adhesive Type | Pressure Sensitive (PSA) |

Warranty | Residential: Limited Lifetime |

Do you need to be a 3M Authorized Window Film Dealer to purchase? | Yes - Not Yet a Dealer? Apply |

Architectural Specifications | |

Technical Data Sheet | |

Warranty | |

Family Card |