ASTM F3561-22 Standard

How effective is a product at delaying or preventing forced entry?

What is the ASTM F3561-22 Standard?

ASTM F3561-22 is a test developed by ASTM International in 2022 to measure a window, door, or modular panel assembly’s resistance to forced entry caused by an active shooter attack. The test, also known as Standard Test Method for Forced-Entry-Resistance of Fenestration Systems After Simulated Active Shooter Attack, is helpful to schools, commercial, residential, and other institutional applications looking to fortify their building envelopes.

The test standard ultimately evaluates the ability to create an opening large enough to allow individual passage to the building’s inside. In other words, how effective is a product at delaying or preventing an individual from gaining entry to the inside of a building by shooting its window glass or other envelope component.

ASTM Test Methods

The test is designed to simulate a situation that has become all too familiar in the United States with respect to K-12 schools - an active shooter that fires multiple times at a school’s curtain wall (i.e. window or door) to gain entry.

During the test, projectiles are fired at the assembly which is then struck by a series of progressively higher impacts. This methodology seeks to mirror an active shooter that fires multiple times and then proceeds to kick through the window or door to enter the premises. There are eight levels of passing.

ASTM F3561-22 does not apply to a retrofit product like window film.

Does F3561-22 Apply to Retrofit Window Films?

If you're researching safety and security window films for installation at a school or religious institution, you've probably seen ASTM F3561 listed as a requirement. On paper, it seems like a logical benchmark. After all, it was developed specifically for forced-entry mitigation in various building environments.

There are certain window film brands that have tested their 23-mil polyester-based films to the F3561 standard. Despite these films passing under certain testing conditions, the International Window Film Association (IWFA), the governing body of the window film industry, asserts that ASTM F3561-22 does not apply to a retrofit product like window film.

The IWFA’s website states the following:

“Neither installed window film nor retrofit glazing incorporated into existing framing or doors is covered under ASTM F3561-22 and the use of this test method to make assumptions about how such glazing would perform under an active shooter attack is not an allowed use of the standard. There is an appendix which does allow glazing to be tested separately, but this appendix is provided to give manufacturers of window and door systems information about what glazing might be used in a full window or door system.”

3M’s Response to F3561-22

3M Company holds the original patent to safety and security window films, dating back to the late 1960s. Since then, 3M has improved upon its original patent through various innovative developments, including multi-layered polyester, urethane as a base film, and structural silicone adhesive as an attachment system. Millions of square feet of 3M security film have been installed on buildings all over the world in response to safety concerns.

Despite 3M’s industry leadership position and innovation in this product category, no 3M safety film, including 3M’s next generation S2400, has been tested to F3561-22.

Like the IWFA, 3M’s position is clear and is stated in a technical bulletin published in response to the ASTM standard:

“The ASTM F3561-22 test method was not designed to evaluate retrofit building window film that would be applied to a wide variety of existing door/entry and window glass systems with differences in glass, framing, locking mechanisms, and other assembly components.”

Window Film Evaluation

A) Physical Properties

An end-user could compare the physical properties of one film to another. Film thickness, tensile strength, break strength, elongation, and Graves Tear are typical film characteristics that are stated in a film specification. This may or may not be a relevant comparison because individual physical properties are not necessarily an indicator of product performance. It also may not be a fair comparison, especially if comparing a polyester or PET-based film to a urethane or TPU-based film. Comparing polyester to urethane is like comparing apples to oranges.

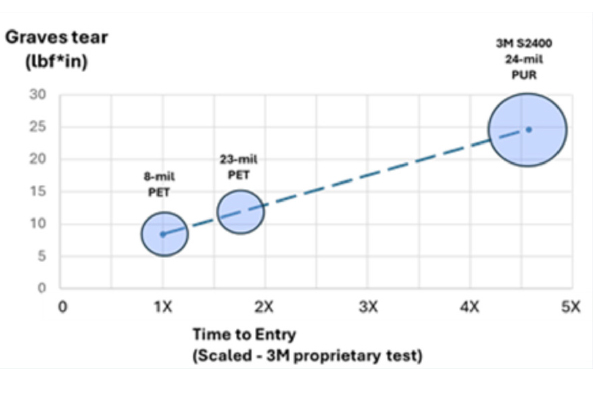

However, generally speaking, urethane films have greater tear resistance, specifically Graves Tear, than polyester films of similar thickness. 3M corporate testing shows that with respect to physical properties, Graves Tear is the best indicator of delaying entry.

In this 3M test, it takes the simulated force more than twice as much time to penetrate a window installed with S2400 as compared to a window installed with a 23-mil PET-based film.

B) Simulated Test Results

Window film manufacturers typically test their products and publish the results. It is not unusual to find various security films tested to staged forced entry attacks. However, the testing methodology from one manufacturer may be different from the next. As such, you’re comparing films in a subjective manner.

A New Standard?

The IWFA may find itself spearheading such efforts based on language found on its website:

“The IWFA and its Technical Committee are currently in conversations with other industry organizations seeking clarification when it comes to the publishing of test results for individual components without indicating that the test report is only for an appendix section of the standard and that “passing” results are not indicative of meeting the requirements of ASTM F3561-22. As a member of ASTM, the IWFA is working along with its members to create a solution that will allow installed window film to have a fair and credible method of comparing performance."

Executive Director Darrell Smith stated “The industry is in a great debt to ASTM and the other testing and standard setting organizations. We look forward to working with them on a solution and to provide clarity going forward for industry professionals and the public.”