Mitigate Bomb Blasts

Mitigate Harm from Bomb Blasts with 3M Window Film

At a Glance

Bomb Blast Mitigation

Optically

Clear

Tested to GSA Standards

Glazed Surfaces: Your Property’s Weakest Link

A New Generation of Blast Film

3M has been manufacturing tough, tear-resistant window films to mitigate the effects of a bomb blast since the late 1960s. However, in 2024, 3M introduced its Scotchshield Safety & Security Window Film System S2400, a urethane-based security film that is more flexible than typical polyester-based (PET) films. This additional flexibility helps to provide greater Elongation at Break (560%) as compared to other films on the market, providing greater tear resistance in certain applications and situations. S2400 has been tested to the following standards:

- 16 CFR 1201

- ANSI Z97.1

- UL 972

3M Impact Protection Adhesive (IPA) Attachment System

Independent GSA Testing

3M Safety & Security Window Films have been tested by independent agencies to the security criteria established by the GSA.

(Testing is available upon request.)

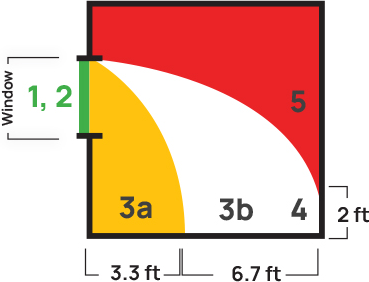

GSA Protection Standard

Performance Criteria | Protection Level | Hazard Level | Description of Window Glazing Response |

|---|---|---|---|

1 | Safe | None | Glazing does not break. No visible damage to glazing or frame. |

2 | Very High | None | Glazing cracks but is retained by the frame. Dusting or very small fragments near sill or on floor acceptable. |

3a | High | Very Low | Glazing cracks. Fragments enter space and land on floor no further than 3.3 ft. from the window. |

3b | High | Low | Glazing cracks. Fragments enter space and land on floor no further than 10 ft. from the window. |

4 | Medium | Medium | Glazing cracks. Fragments enter space and land on floor and impact a vertical witness panel at a distance of no more than 10 ft. from the window at a height no greater than 2 ft. above the floor. |

5 | Low | High | Glazing cracks and window system fails catastrophically. Fragments enter space impacting a vertical witness panel at a distance of no more than 10 ft. from the window at a height greater than 2 ft. above the floor. |

3M’s fragment retention films are maintenance-free, vary in thickness (from 4 mils to 24 mils*), and provide some of the energy benefits associated with 3M sun control films.

*1 mil = .001 inches

Product Information

Segment Card | |

Product Specifications | |

Warranty |