Energy Modeling

Estimating the Impact of Energy Efficiency Improvements

An energy model can estimate the environmental and financial impact of a proposed energy efficiency improvement, including window film, to a building. Developing an accurate model takes resources, research, time, and commitment. The confidence of having sound knowledge on which to make a capital improvement decision is worth the effort.

We provide energy modeling assistance in two ways:

In-House Modeling

Using software co-developed by the US Department of Energy (DOE) and the International Window Film Association (IWFA), 3M can estimate the impact that window film will have on utility savings and energy consumption. We model your building as it is today and model your building as it would be with the addition of window film. We then compare the energy consumption (gas and electric) of both to determine savings. Most 3M window films have a projected payback of up to seven years before any utility rebates, grant assistance, or penalty avoidance. The software calculations are conservative and actual results may be well below that range.

View a sample EFILM Energy Analysis (PDF)

Energy Modeling Assistance

A building that has been making energy efficiency upgrades throughout the years may have an existing and accurate energy model already on hand. Whether maintained in-house or by a third party, EPD can provide its clients with the 3M window film plug-ins for eQUEST or TRACE 700 on a building’s specific glass type. This provides a client a good understanding of the effectiveness of 3M window films using a model in which the client already has confidence.

Download 3M Window Film Plug-Ins for eQuest (ZIP)

Download 3M Window Film Plug-Ins for Trace 700 (ZIP)

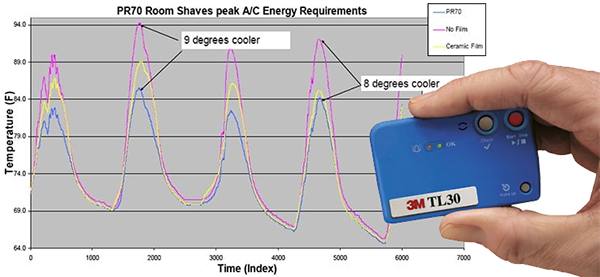

Temperature Logging

In addition to energy modeling, 3M and EPD can estimate the impact of window film on temperature within the building. After identifying two identical rooms in terms of size and window area that are side by side or on top of one another, we will install window film in one room and leave the other untreated as a control. We then set up temperature loggers that read and record temperatures over time. After a week’s time, we extract the data from the loggers and have shown as much as a 16°F difference.