3M Low-E Window Films

Simulate Low-E Windows With Window Film

3M Low-E Window Films are designed to turn existing glazing into Low-E glass in a cost-effective manner. These films keep out the sun’s heat in the summer and retain man-made heat during the winter, just like Low-E glass. Adding a 3M Low-E window tint is almost like adding an extra pane of glass, but at a fraction of the cost of window replacement. 3M offers a few clear and colorless films that don’t really change a window’s appearance.

At a Glance

Simulate Low-E Windows

Reduce Carbon Footprint

Reduce Heating Bills

Nearly Invisible

Warrantied by 3M

3M All Season Low-E Window Films

3M Company introduced insulating Low-E window films in the early 1970s as a solution to transform standard glass into Low-E glass. As such, these unique tinted films not only lower a window’s Solar Heat Gain Coefficient, but also its U-Value. This decrease, in turn, helps buildings reduce energy consumption from HVAC system usage (heating and cooling) year-round.

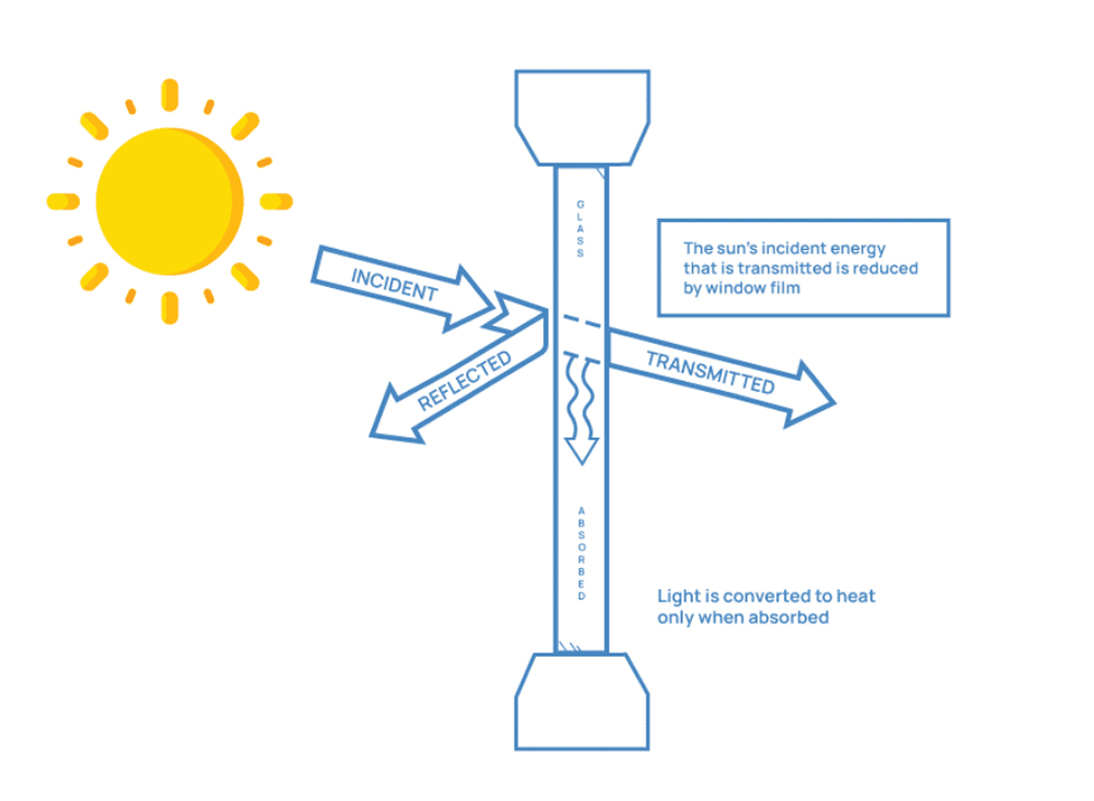

Cooling Season

During the cooling season (hotter months), window film increases the amount of the sun’s incident energy that is reflected and absorbed by the glass, thereby reducing what is transmitted into the building.

Heating Season

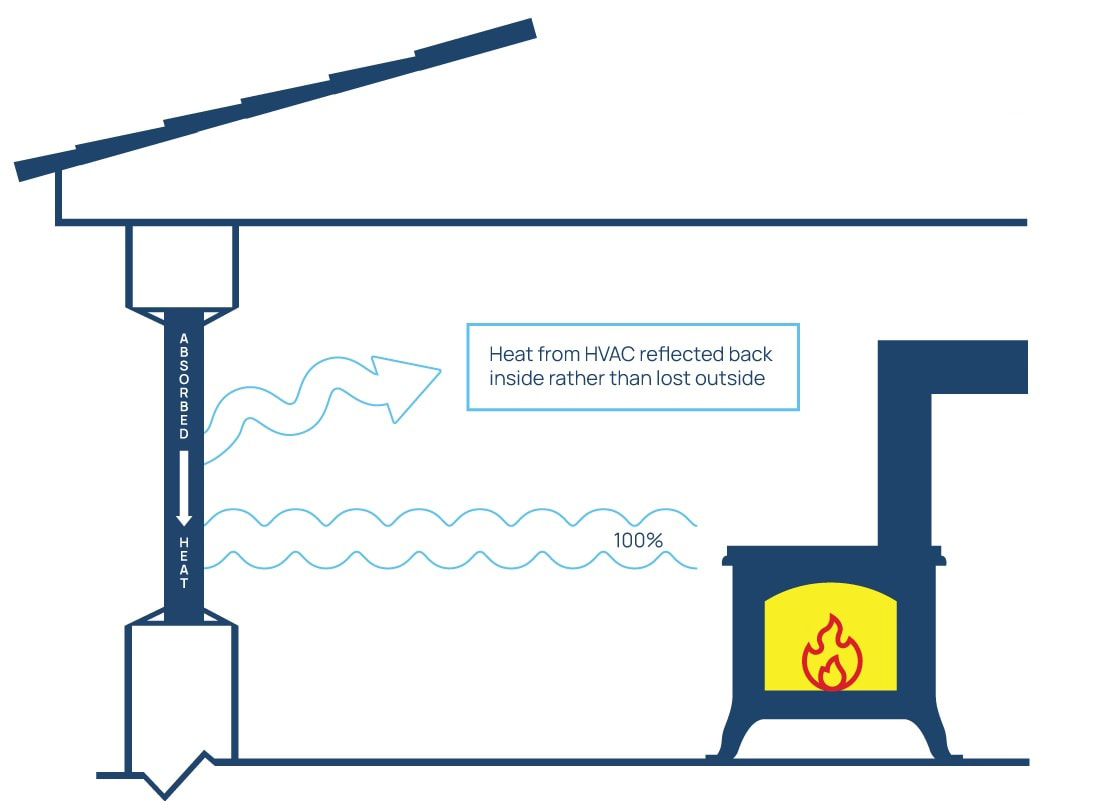

During the heating season (colder months), window film increases the amount of man-made heat from the HVAC system that is reflected back inside the glass, thereby reducing what is lost to the outside.

Why are Low-E Windows Important?

Science tells us that heat travels from places of hot to cold. Heat generated from an HVAC system (furnace, boiler, etc) wants to go where it’s cold, which is outside. It travels outside through the path of least resistance, which is often through a window. The metallized coating of a Low-E window increases the resistance of heat passing through glass by reflecting it back inside. Reducing this heat loss means that the HVAC system consumes less energy (gas, electric, steam, oil).

Impact of Low-E Film

The table below illustrates the impact of a Low-E film like 3M Thinsulate Climate Control CC75 to the U-Value and Solar Heat Gain Coefficient (SHGC) of standard clear glass windows. The numbers speak for themselves. Adding 3M Thinsulate Climate Control Window Film lowers a window’s SHGC and U-Value considerably, almost to the same extent as replacing single pane glass with double pane, or double pane glass with triple pane.

Window Type | U-Value Before | U-Value After | Improvement | SHGC Before | SHGC After | Improvement |

|---|---|---|---|---|---|---|

Single Pane (1/4") | 1.03 | 0.62 | 40% | 0.82 | 0.53 | 35% |

Double Pane (1/4", 1/2" air gap, 1/4") | 0.47 | 0.35 | 26% | 0.70 | 0.51 | 27% |

The Value Proposition

Low-E window films like 3M’s Thinsulate Climate Control CC75 or LE-70 present a compelling value proposition to commercial buildings looking to upgrade existing glazing for carbon footprint reduction. Mandates such as New York City’s Local Law 97, Boston’s Building Energy Reduction and Disclosure (BERDO), and Washington’s Clean Energy DC force building owners to increase the efficiency of their curtain wall glazing in order to reduce heating consumption, and subsequently, carbon footprint. If window replacement is feasible, it is a significant undertaking, being expensive and disruptive to tenants. 3M Low-E Window Films are a cost-effective alternative. Consider the following options:

Cost of window replacement

$5,000 per pane

Cost of

window insert

$2,000 per pane

Cost of 3M Thinsulate Window Film

$500 per pane

From a performance standpoint, window replacement is the most effective solution. Neither inserts nor Low-E window films offer the same energy benefits, yet replacement is often unfeasible, especially if the building’s structure is unable to withstand the additional weight of significantly better glazing.

Given the significant cost savings of Low-E window tint over replacement or inserts, the value proposition is clear.

Warranty

3M Low-E Window Films are warrantied by 3M Company against premature product failure (bubbling, cracking, crazing, peeling, blistering, delamination, and discoloration). 3M also protects against thermal shock fracture and seal failure for up to 60 months and 40 months, respectively, depending upon the application. (Please see the warranty for terms and conditions.)

Product Information

Brochure | |

Family Card |