Table of Contents

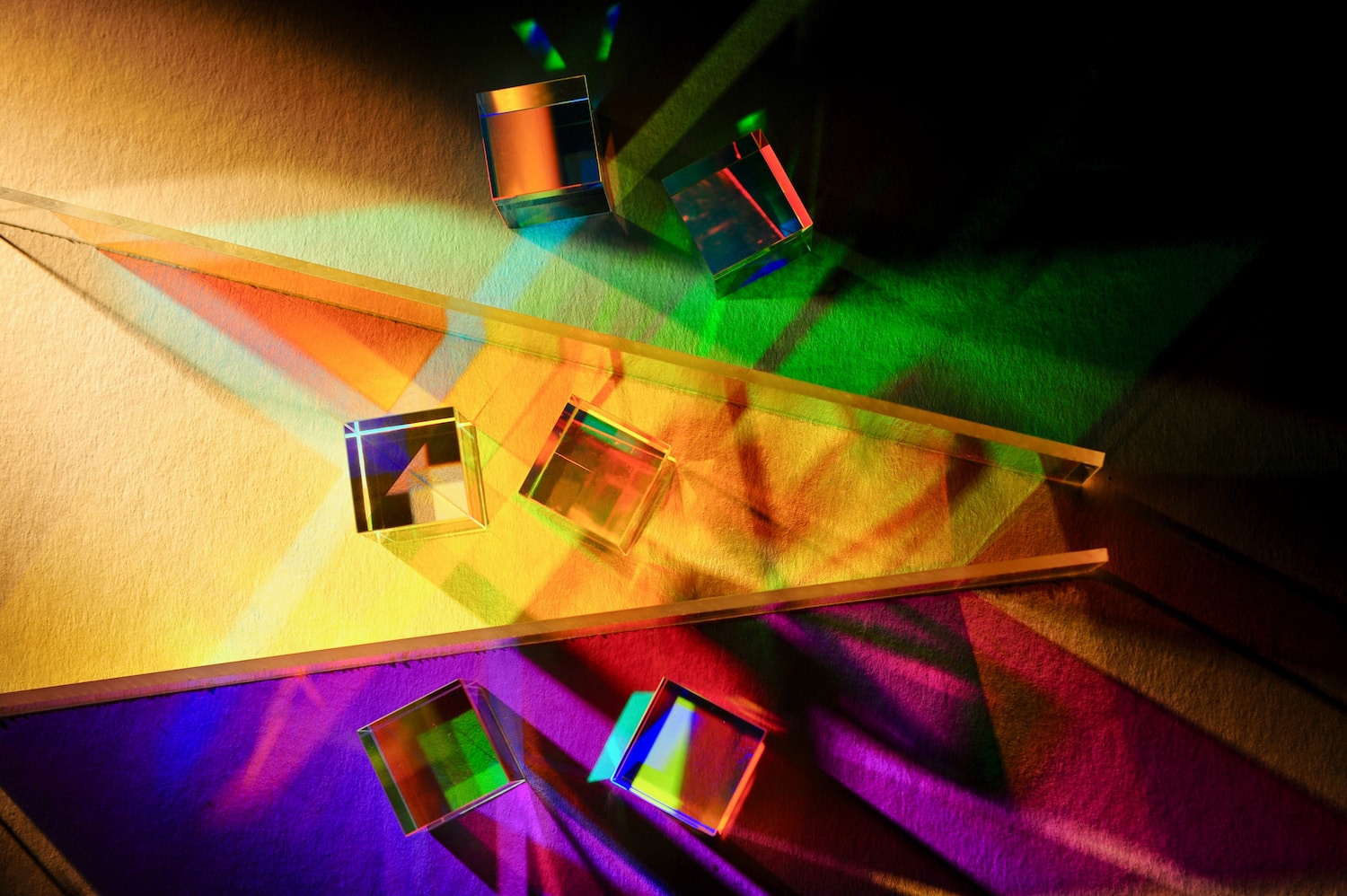

What is Dichroic Glass?

Dichroic glass is a highly specialized type of glass that displays two different colors by reflecting one color and transmitting another through an intricate process of light refraction. This style of glass has origins dating back to ancient Roman and Egyptian eras, where it was crafted to emulate the appearance of precious stones. Contemporary dichroic glass was initially developed for scientific purposes within the aerospace industry, and it is now utilized in various fields for its unique aesthetic appeal and ability to add a touch of iridescence to objects and spaces.

Why is Dichroic Glass So Expensive?

There are several factors that contribute to the high cost of dichroic glass:

- Intricate Manufacturing Process: The production of dichroic glass is an intricate process that involves layering ultra-thin layers of metal oxides, and sometimes quartz crystal, onto the glass. The precision required is high, and the thickness of each layer is crucial to the glass’ color and reflective properties.

- High Material and Equipment Costs: The raw materials, such as quartz crystal and metal oxides, are costly. Additionally, the advanced equipment required for production adds a significant expense.

- Expertise and Labor Intensity: The creation of dichroic glass demands a high skill level and extensive labor. The artisans responsible for its production must possess a deep understanding of both the artistic and scientific aspects of the glass.

- Wastage and Quality Control: The production process is delicate, with a relatively high wastage rate. Ensuring that only top-quality dichroic glass reaches the market necessitates rigorous quality control, further elevating the cost.

Why 3M Dichroic Film is an Ideal Alternative to Dichroic Glass

3M Dichroic Film serves as an excellent alternative to dichroic glass due to several advantages, particularly in terms of cost, ease of application, and versatility:

- Cost-Effectiveness: The materials and process required for film manufacturing are significantly more cost-efficient than that of dichroic glass, making it a budget-friendly option for achieving a similar iridescent effect. In some projects, the use of dichroic film can be between 10% and 20% of the cost of using dichroic glass.

- Ease of Application: Dichroic film can be easily applied to existing glass surfaces, eliminating the need for replacing entire glass structures. This allows for the transformation of a space without extensive labor or structural modifications.

- Flexibility in Design: Unlike the rigid nature of glass, dichroic film can be easily cut into different shapes and sizes, offering a higher degree of customization for specific project requirements.

Examples of 3M Dichroic Film Applications

In summary, while dichroic glass brings mesmerizing visual appeal to its many applications, dichroic film offers a practical and versatile alternative with benefits in cost savings, ease of use, and design flexibility. It’s an innovative solution that enables designers and consumers to explore the unique beauty of dichroic aesthetics in a more accessible and adaptable format.

Energy Products Distribution is a Master Distributor of 3M Window Films, 3M Paint Protection Films, 3M Wrap Film Series 2080, 3M Protection Wrap Films, 3M Architectural Finishes, 3M Ceramic Coatings, and Windshield Skin. We sell our products to professional installers throughout the US who provide turnkey installations (labor and material) to end-users in the automotive, commercial, government, and residential markets. Contact us to learn more about the benefits of these products.